The Well-Built Well: Constructing a Lasting Wood Window Well

Share

Why Window Well Wood Construction Matters for Your Home

Window well wood construction offers a natural, customizable alternative to standard metal or concrete. Unlike mass-produced options, wooden wells can be shaped to match your home's architecture and landscaping.

Quick Answer for Building Wood Window Wells:

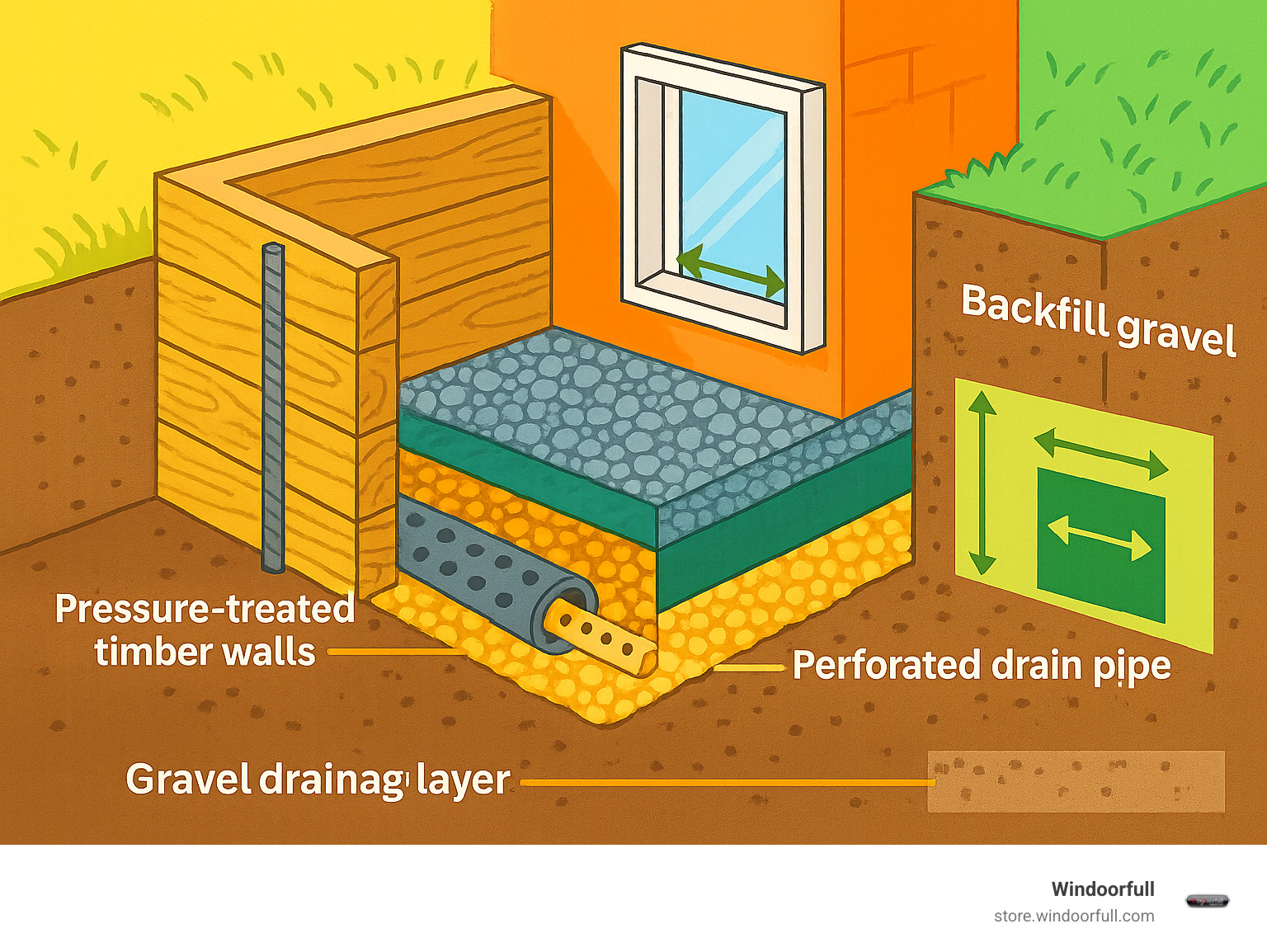

- Use pressure-treated lumber rated for ground contact.

- Follow IRC codes for size: minimum 36" wide, 9 sq. ft. area.

- Install proper drainage with a gravel base and drain pipe.

- Secure stacked timbers with rebar.

- Seal all cut ends to prevent moisture damage.

- Plan for maintenance and inspect annually for rot.

Wood window wells are easy to build into any shape, allowing you to incorporate steps directly into the design. They provide a much more natural aesthetic that complements home exteriors beautifully. However, wood requires regular maintenance to combat moisture. As noted in industry research, wood breaks down as moisture in the soil begins to penetrate, causing it to rot and require replacement.

This guide will walk you through building a durable wooden window well that maximizes its aesthetic benefits while addressing maintenance needs through proper construction. I'm Wojciech from Windoorfull Imports Inc., and my experience with European-style tilt-and-turn windows has shown me how a proper window well improves both safety and home value.

Why Build a Window Well? The Foundation of Safety and Light

A window well is more than just a hole in the ground; it's a critical feature for safety, light, and home protection. Here's why building one is a smart investment.

- Emergency Egress: Building codes require egress window wells for any basement sleeping area for a crucial reason: they provide a life-saving escape route during a fire when stairs may be blocked. A properly built window well wood structure ensures you and your family have a way out.

- Natural Light: A well-designed window well transforms a dark, cave-like basement into a bright, welcoming space. Sunshine can stream into a basement office or family room, making it a place where people want to spend time.

- Basement Ventilation: Window wells enable fresh air to circulate, helping to eliminate musty basement smells. This is especially beneficial when paired with versatile windows like our European-style tilt-and-turn models, which can be tilted for gentle airflow or swung open for maximum ventilation.

- Foundation Protection: A window well acts as a barrier, keeping soil pressure and moisture away from your window frames. This prevents rot, mildew, and seal damage that can lead to costly repairs.

- Soil Retention: By holding back the earth, a window well prevents soil from shifting against your foundation. This reduces hydrostatic pressure that can cause leaks and structural issues.

Combining a well-built window well with modern European engineering like our tilt-and-turn windows creates a safer, brighter, and more comfortable living space.

Planning Your Project: Codes, Design, and Materials

Proper planning is the key to a successful window well wood project. Before you start, focus on understanding building codes, finalizing your design, and selecting the right materials.

Understanding Egress Window Well Codes

Building codes for egress wells exist for safety and are non-negotiable. While the International Residential Code (IRC) provides a baseline, always check with your local building department for specific local requirements.

Key IRC minimums for a window well wood structure include:

- Area: At least 9 square feet of horizontal space.

- Projection: Must extend at least 36 inches from the foundation wall.

- Width: Must be at least 36 inches wide.

- Ladders/Steps: A permanent ladder or steps are required if the well is deeper than 44 inches. This is a great opportunity for built-in wooden steps.

- Covers: Any cover must support 40 pounds per square foot and be openable from the inside without tools.

You can find building code details here for more information.

Designing for Aesthetics and Function

This is where window well wood construction excels. Unlike standard metal wells, wood offers immense design flexibility.

- Custom Shapes: Create curved or geometric designs that complement your home's architecture.

- Tiered Levels: Add visual interest and create small planting areas within the well.

- Built-in Steps: Seamlessly integrate code-required steps that improve the well's appearance.

- Landscaping Integration: Design the well to look like an intentional garden feature, blending it with decorative stones, decking, or flower beds.

Choosing Materials for a Durable Window Well Wood Structure

To build a lasting window well wood structure, you must manage moisture effectively.

- Lumber: Use pressure-treated lumber with a ground-contact rating. This wood is treated with extra preservatives for burial applications.

- Sealer: Seal all cut ends with a wood preservative immediately after cutting. This prevents moisture from entering untreated areas.

- Fasteners: Use structural screws designed for outdoor use and rebar driven through stacked timbers for maximum stability.

- Drainage Components: A proper drainage system is crucial. You'll need geotextile fabric to prevent clogs, a gravel base (3/4-inch clean stone), and a perforated drainage pipe to channel water away.

Learn about pressure-treated wood to better understand its properties.

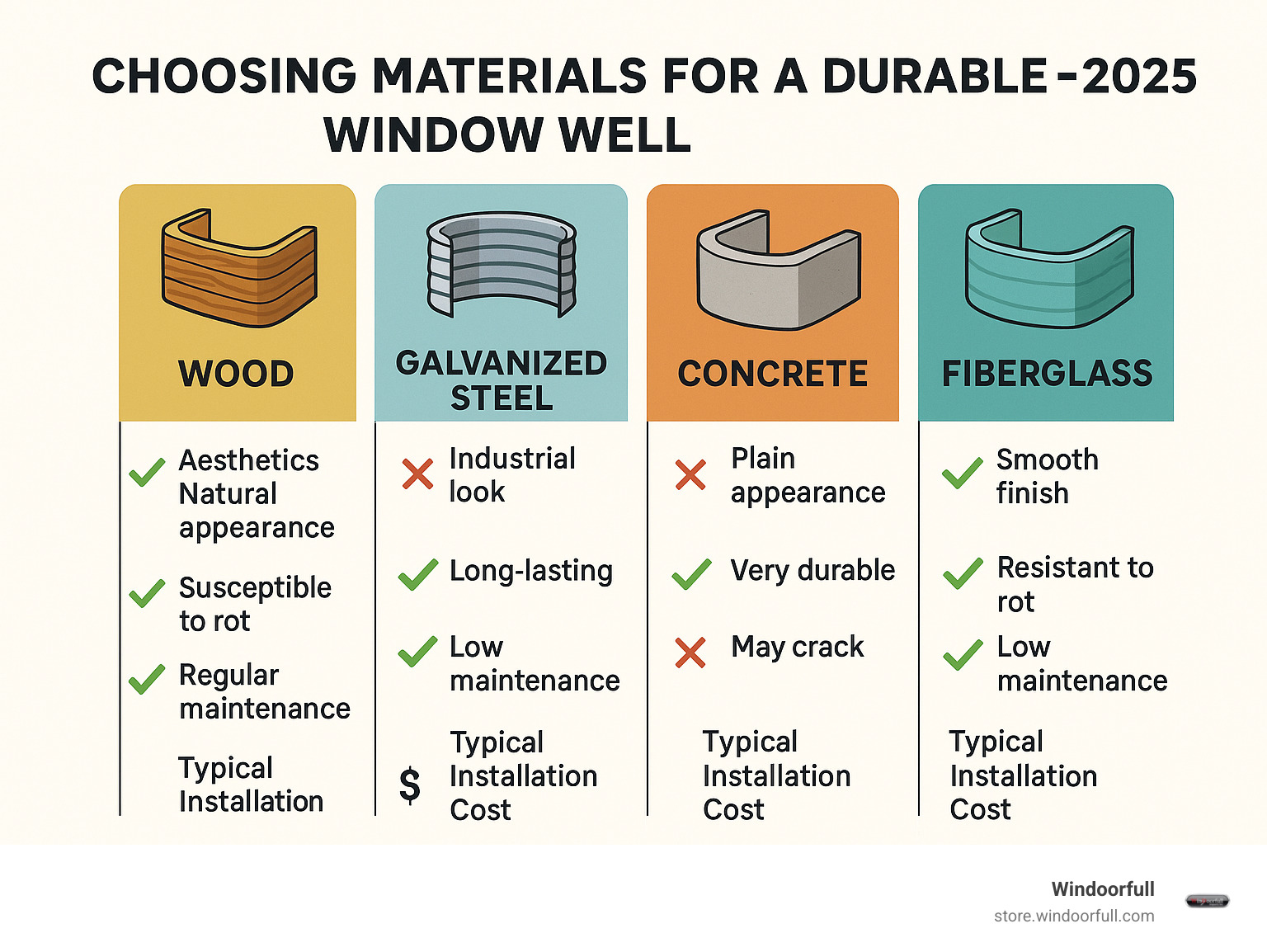

Wood vs. Other Materials: A Quick Comparison

While window well wood offers best customization, it's important to see how it compares to other common materials. Understanding these trade-offs will help you choose the best option for your home and budget.

| Feature / Material | Wood (Pressure-Treated) | Galvanized Steel | Concrete | Fiberglass |

|---|---|---|---|---|

| Aesthetics | Natural, warm, customizable, blends with landscaping. | Industrial, can be painted or lined for aesthetics. | Robust, utilitarian, can be faced with stone. | Smooth, modern, often mimics natural textures. |

| Durability/Lifespan | 10-20+ years (with maintenance), susceptible to rot. | 30+ years, weather-proof, rust-resistant (galvanized). | Very long, durable, but can crack/crumble. | Very long, strong, lightweight, no rust/rot. |

| Maintenance | Regular sealing/staining, inspect for rot, good drainage. | Low, occasional cleaning, inspect for rust. | Low, may need crack repair, touch-ups. | Low, occasional cleaning, inspect for UV damage. |

| Typical Installation Cost | Moderate (DIY-friendly, material cost). | Moderate to high (pre-fabricated). | Moderate to high (labor-intensive, heavy). | High (pre-fabricated, specialized). |

For aesthetics, wood is the clear winner, blending seamlessly with landscaping for a natural look. Other materials tend to look more industrial or manufactured.

However, wood requires the most maintenance. Regular sealing and inspections are necessary to achieve a 10-20+ year lifespan and prevent rot. Steel, concrete, and fiberglass are more durable and require less upkeep.

Wood's main advantages are its DIY-friendliness and customizability. You can easily create custom shapes and built-in steps, a level of flexibility not found in pre-fabricated units. This makes window well wood a popular choice despite the higher maintenance. The installation cost is also moderate, especially for a DIY project.

While wood requires more care, many homeowners find the aesthetic results are worth the effort, especially when paired with quality windows like our European-style tilt-and-turn models.

Step-by-Step: How to Build Your Window Well Wood Masterpiece

With your plan in place, it's time to build your window well wood structure. Follow these steps for a successful DIY project.

Step 1: Excavation and Foundation Prep

First, call 811 (Dig Safe) a few days before digging to have underground utilities marked. This is a critical safety step. Once clear, use stakes and string to mark your layout, ensuring it meets code requirements (min. 36" width, 9 sq. ft. area).

Dig to the proper depth, allowing room for the drainage system below the window sill and the height of your timber walls. The base of the excavation should slope gently away from the foundation. Finally, clean the foundation wall where the well will attach, scraping away dirt and debris to ensure a solid connection.

Step 2: Installing a Robust Drainage System

A proper drainage system is the key to preventing rot in a window well wood project.

- Slope the base of the excavation away from the foundation.

- Add a 6- to 12-inch gravel layer of clean, 3/4-inch stone to create a permeable bed.

- Install a perforated drain pipe (PVC is ideal) with the holes facing down. Connect it to your home's perimeter drain system or a dry well.

- Cover the gravel and pipe with landscape fabric (geotextile) to prevent soil from clogging the system. Extend the fabric up the sides of the excavation.

Step 3: Assembling the Timber Walls

Now, bring your design to life.

- Cut your timbers to length and immediately seal the cut ends with a wood preservative to block moisture.

- Stagger the joints of each layer, like a brick wall, for strength and stability.

- Secure the layers by driving heavy-duty structural screws through each timber. For maximum stability, drill pilot holes and drive rebar vertically through multiple layers.

- Anchor the top timber to the foundation using concrete anchors or lag screws. This adds structural integrity and prevents water intrusion.

Step 4: Backfilling and Finishing Touches

The final steps complete the project and ensure long-term durability.

- Backfill with gravel around the outside of the timber wall. This promotes drainage and prevents direct soil contact with the wood.

- Grade for water runoff by shaping the surrounding topsoil to slope away from the foundation and the new well.

- Install a window well cover. A cover keeps out debris, prevents accidents, and is required for egress wells. Ensure it can be opened easily from the inside without tools.

Long-Term Care: Maintaining Your Wood Window Well

A window well wood structure requires simple, regular maintenance to ensure it lasts for decades. Developing a few good habits will prevent major issues and keep your well looking great.

- Regular Inspections: Twice a year (spring and fall), inspect the timbers for cracks, bowing, rot, or insect damage. Pay close attention to the bottom layers, which are most exposed to moisture.

- Clean Out Debris: Regularly remove leaves, dirt, and twigs from the well. Decomposing organic matter traps moisture and accelerates rot.

- Check Drainage: After heavy rain, ensure water is not pooling in the well. If you see standing water, your drain may be clogged. A simple flush with a garden hose can often clear minor blockages.

- Re-seal or Stain: Every few years, apply a quality water-repellent sealer or stain to protect the wood from UV rays and moisture. Ensure the wood is clean and dry before application.

- Pest Prevention: Keep the area around the well clear of debris to discourage termites or carpenter ants. Good drainage is your best defense against pests.

A well-maintained window well wood structure is a long-term asset. For more insights on keeping your windows and surrounding structures in top shape, check out our blog: More info about window care.

Frequently Asked Questions about Wooden Window Wells

Here are answers to the most common questions about building a window well wood structure.

How long will a pressure-treated wood window well last?

With proper construction and consistent maintenance, a pressure-treated window well wood structure can last 10 to 20 years or more. The lifespan depends on factors like climate, soil conditions, and the quality of the lumber. However, maintenance is the most critical factor. Regular cleaning, ensuring good drainage, and re-sealing the wood every few years are essential to prevent rot and maximize the well's life.

Can I build steps directly into my window well wood design?

Yes, absolutely. This is a major advantage of using wood. You can easily cut and assemble timbers to create built-in steps, which are both functional and aesthetically pleasing. For wells deeper than 44 inches, steps or a ladder are required by code for egress. Integrated wooden steps are a far more attractive solution than a metal ladder and can double as shelves for plants.

Do I need a window well cover for my new well?

For egress windows, a cover is typically required by code. It must support at least 40 pounds per square foot and be easily opened from the inside without tools.

Even if not required, a cover is highly recommended for any window well. It provides several key benefits:

- Safety: Prevents accidental falls.

- Cleanliness: Keeps out leaves, dirt, and debris that trap moisture against the window well wood.

- Drainage: Reduces the amount of rain and snow entering the well.

A quality cover is a smart investment that protects your well and improves safety.

Conclusion

Building a window well wood structure is a rewarding project that improves your home's safety, functionality, and beauty. You've created a vital emergency escape route, brought natural light into your basement, and added a beautiful, custom feature to your landscape.

The key benefits you've achieved include:

- Custom Beauty: Unlike standard metal wells, a wooden well is uniquely yours, with design possibilities like built-in steps or custom shapes.

- Improved Safety: A code-compliant egress well provides peace of mind and a critical escape route for your family.

- Project Satisfaction: There's immense satisfaction in building a durable, functional feature with your own hands.

While your window well wood requires regular maintenance, the effort is a small price for a beautiful and functional addition to your home.

At Windoorfull, we believe thoughtful projects like this make a house a home. A custom wooden window well is the perfect complement to our European-style uPVC tilt and turn windows, which offer versatile ventilation options.

Ready for your next project? Explore our blog for more home improvement insights and see how the right windows can lift your home.